Shuttering Magnet Formwork System Precast Concrete Magnets

Basic Info

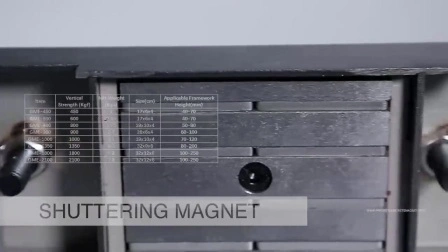

| Model NO. | GME-450/600/900/1350/1800, etc. |

| Material of Magnetic Hooks | Magnet + Stainless / Plastic |

| Grade | N52 |

| Shape | Block |

| Coating | Spray-Paint |

| Pull Force of Magnetic Hooks | 450--2100kgs |

| Application of Magnetic Hooks | Industrial Building |

| Lead Time of Magnetic Hooks | 7-10 Days |

| Payment | T/T, Paypal, Western Union |

| Transport Package | Carton, Wood Case, Anti-Magnetized Package |

| Specification | 17x6x4CM, etc. |

| Trademark | GME precast concrete magnet |

| Origin | Zhejiang China |

| HS Code | 85051190 |

| Production Capacity | 3000 Tons |

Product Description

Precast Concrete magnetformwork system Precast Concrete magnets shuttering Magnet

With the developing of construction industry, the precast concrete has been formed into a new green commercial mold to site-cast concrete. It's already being applied in a wide range of walls, floors and even roofs from private house to a giant building with much more durability, flexibility and of course economically.Compared to the old site-cast model, the new precast has many advantages. Due to these brilliant performances, many construction companies are adapting it as their new working method from Europe, Southern America to USA, India and now spread to China as well.As an important accessory for precast concrete system, shuttering magnets are designed to fix the panel when pouring the concrete to the molds.Shuttering magnets, which is suitable for all kinds of formwork construction as steel and plywood shuttering system with appropriate adaptor, are composed with very strong permanent magnets ( neodymium magnet) and a shielding steel box. The workers could push or pull the above button to make the magnetic box performed adhesive force or not with a steel sticker. It's very easy to control according to requirements.

Product Description:

Our design of Precast Concrete Magnet for the precast concrete industry is so compact and light-weight, as a result of the application of the modern neodymium magnetic materials, our shuttering systems offer an excellent magnetic power compared to the minimum weight of the products themselves.The magnetic tools can be used in any concrete formwork applications. We can offer different size and magnetic force of magnetic systems to meet our customers' requirements. The biggest advantage of our product is so light-weight but strong adhesive force, such as the weight of the magnet is only 7.2 kg while the adhesive force could reach about 1800 KGs.

User's Instructions

1)The main purpose and features:

Precast Concrete Magnets is specifically designed and developed for fixing precast concrete formwork.Compared with the traditional method that being fixed by screw and other mechanical fixation, Precast Concrete Magnets are advantaged in compact structure, easy operation, strong suction strength, Safe and reliable features, which are conducive to improving labor efficiency, so, More and more Precast Concrete Magnets are used widely in the pre-cast concrete production lines home and aboard.

2) The main structure and specification

Precast Concrete Magnets made of high-performance permanent magnet material to create a strong suction force. Through the switch, the magnets can be off and on status. When ON status, the bottom surface of magnet will be closely fitted on the production platform of the precast concrete.When the magnet is pried by crowbar, the magnetic field will be greatly reduced, the magnet can be remove from the platform easily by hand.

Main Technical Specification:

3) How to use:

(1) Press the magnetic switch, the magnet fit on platform very firmly.Pry the switch by crowbar, the magnetic strength on platform will be weaker and remove the magnet.(2) Platform thickness and surface smoothness will affect the magnetic suction between the magnet and the platform, the thicker and the more smooth the platform is, the stronger suction strength is. Lateral shear force is related with the magnetic strength and surface friction.(3) The two fixed screws on the end of precast concrete magnet can connect with different fixture, in order to fix different structure side mold, such as angle steel, channel side die mold and so on.

[Releasing Tools]

After project or production finished, the workers needs to release the magnets with a steel bar tool. The steel bar is around 1 meter long.

Application:Package & Shipping:

Don't hesitate to add your favorite list!

GME core values

Customer Care

Quality is our life. Customer satisfaction is our eternal pursuit. Everything we do at GME is driven by an unyielding passion for excellence in identifying and delivering solutions that exceed expectations.

Innovation

In today's fast-developing global economy, innovation is critical to a company's survival. We anticipate and adapt to changing for continuous improvement.

Co-Prosperity

A business cannot be successful unless it creates prosperity and opportunity for others. We have a dream--customers could win more through our Great Service; we have a dream--GME members could realize their own dreams while striving for GME Dream.

Social Responsibility

Sustainability isn't only important for people and the planet, but also is vital for business success. We are environmentally responsible and drive to sustainability. And we should do something for our better future.